CPI WILEY

Wiley and CPI Group UK bring Print & Distribution operations together under one roof. The partnership delivers a sustainable, end-to-end supply chain solution for the publishing industry

The collaboration focuses on a range of print strategies, including Print on Demand, Zero Inventory and ultra-short run Auto Stock Replenishment. Combining Wiley’s distribution experience, CPI’s digital print expertise and the inventory analytics that both parties offer, the partnership gives publishers granular visibility into the full cost of production, supporting overall cost savings through effective stock management, perpetual availability of ISBN’s, demand planning and full-service distribution delivery.

BENEFITS OF CPI WILEY

-

Delivery of a more environmentally sustainable approach to the traditional publishing supply chain

-

Provide customers with a broader range of content from a single location; ensuring both persistently available inventory and a delivery in the same timeline and in the same carton/shipment as traditionally stocked inventory

-

Provide the local community with additional employment opportunities and with an improved set of skills

-

Reduce waste, and obsolescence, leading to dramatic reduction in carbon emission, and reduces cash tied up in inventory

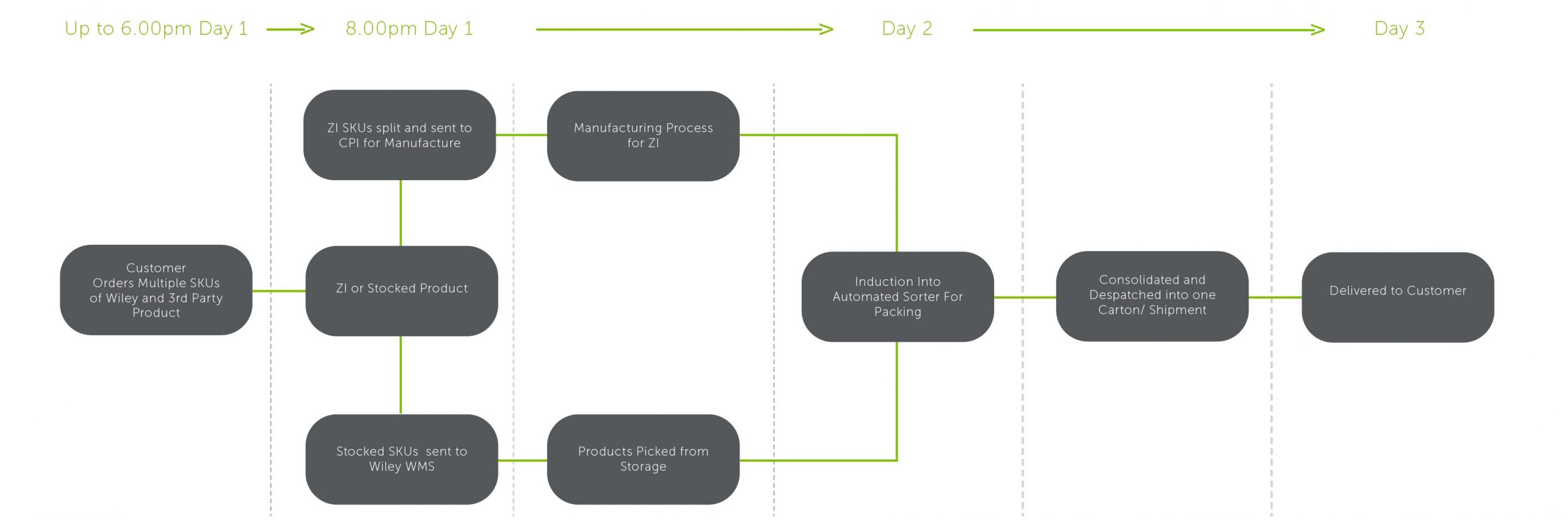

- Manufacturing turnaround time of under 24 hours, ensuring the SLA for stocked and printed books is the same.

How does it work ?

- First the publisher builds a catalogue of ISBN’s to be available in this programme with CPI. CPI is able to support publishers through this part of the programme with resource in pre-press and metadata management if required.

- Once a catalogue is built all ISBN’s are visible to sales channels as in-stock and available to order.

- An order will be received and if it’s not a stocked item it will be passed to CPI for overnight manufacture.

- Once produced the finished book is returned to the distribution order flow and continues to be consolidated and shipped as part of a regular customer order.